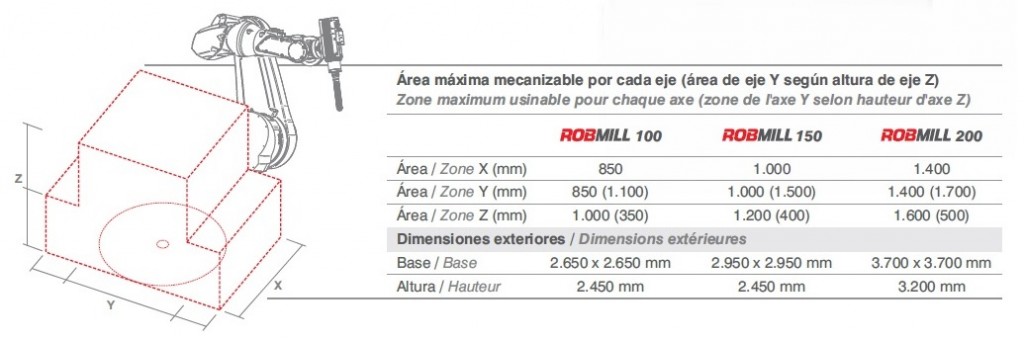

ROBMILL solutions group together maximum machining capacity in a minimum space, offering considerable flexibility and fast machining.

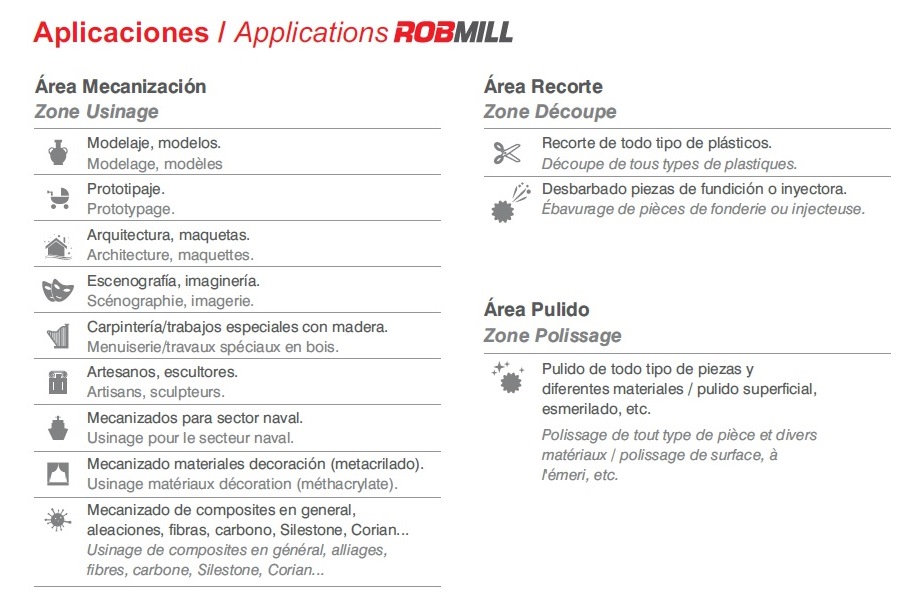

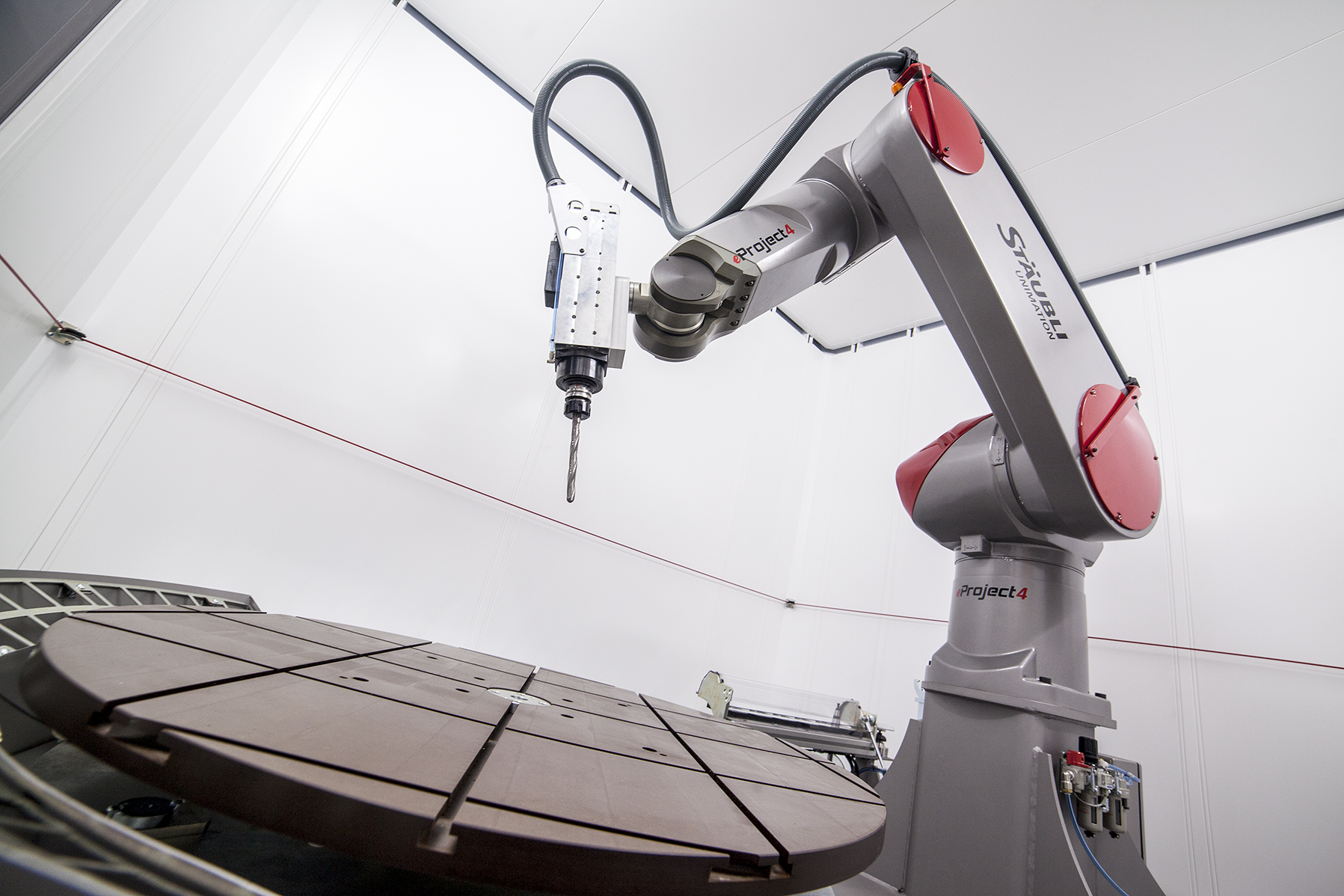

ROBMILL, in its standard configuration, is a machining solution based on a turntable and a high performance robot. Its monoblock structure allows the assembly to have high rigidity and stability. This central control integrates a CNC that makes it a completely innovative solution that has far superior features than what is offered in this type of format. The solution is configurable and can be adapted to different market solutions; all kinds of machining, deburring, cutting, polishing, etc.

CNC

- Full control of all axes (6 from the robot + rotary axis) in real time on the same platform (B&R), improving interpolation and real speed control at the tool’s point.

- Interpretation of ISO-G code, which allows a connection with any CAD-CAM on the market.

- Easy and intuitive touch-screen interface for the user.

- Ethernet connection.

- Modem connection option.

Safety closure

- Two configurations available.

- Insulated and soundproof safety enclosure with an access safety system that follows EC regulations.

- Safety enclosure by means of perimeter fence.

- All security and control elements are always incorporated for proper compliance with existing safety standards.